3D PRINTERS

A PERFECT SOLUTION TO 3D-PRINT CERAMIC PRODUCTS

AON manufactures and supplies bio-ceramic 3D printers and the materials to customers over global markets who want to transform their current carving, milling, molding production process into 3D-printing production process. The 3D printer is easy to use, and competitive from performance and price perspective. The materials are tested and proved bio-compatible, safe and reliable.

ZIPRO Dental

| Printing Method | DLP |

| Product Size/Weight (W x L x H, mm) | 570 x 510 x 1020 / 70Kg |

| Build Volume’ (W x L x H, mm) | 76.8 x 43.2 x 75 |

| Ambient Temperature | 15~35℃ |

| Power/Consumption | AC 110~240V / 50/60Hz, 95-134VA |

| Lateral Resolution | 40µm |

| Light Source | 405nm wavelength Ultraviolet LED |

| Number of pixels (X,Y) | 1920 x 1080 |

| Speed | Up to 6mm per hour, when printing at 50µm per layer, up to 12mm per hour, when printing at 100µm per layer |

ZIPRO Industrial

| Printing Method | DLP |

| Product Size/Weight (W x L x H, mm) | 570 x 510 x 1020 / 70Kg |

| Build Volume’ (W x L x H, mm) | 107.5 x 60.5 x 150 |

| Ambient Temperature | 15~35℃ |

| Power/Consumption | AC 110~240V / 50/60Hz, 95-134VA |

| Build Layer Capability | 25µm to 100µm per layer |

| Light Source | 405nm wavelength Ultraviolet LED |

| Number of pixels (X,Y) | 40, 50, 56 µm |

| Speed | Up to 6mm per hour, when printing at 50µm per layer, up to 12mm per hour, when printing at 100µm per layer |

ZIPRO-D Dental

| Size | 510mm X 540mm X 650mm |

| Weight | 53kg / 117lbs |

| Box Size/Weight | 560mm x 640mm x 860mm / 73Kg |

| Ambient Temperature | 15~35℃ / 59~95°F |

| AC Adaptor | AC 100~240V, 50/60Hz, 96~136VA |

| Printing Technology | DLP(Digital Light Processing) |

| Build Size | 76.8mm X 43.2mm X 65mm |

| Pixel Resolution | 40 µm |

| Pixel Size | 1920 X 1080 |

| Layer Thickness | 50 micron meter |

| Source of Light | 405nm |

INNI

INNI for the purpose of education or training

| Printing Method | DLP |

| Product Size/Weight (W x L x H, mm) | 480 x 370 x 543 / 46Kg |

| Build Volume’ (W x L x H, mm) | 107.5 x 60.5 x 150 |

| Ambient Temperature | 15~35℃ |

| Power/Consumption | AC 110~240V / 50/60Hz, 95-134VA |

| Build Layer Capability | 25µm to 100µm per layer |

| Layer Thickness | 50µm per layer |

| Printing Resolution | 1280 x 8006 µm |

MATERIAL

INNI-CERA

| Product Name | ININI-CERA (BCM-W500/1000) |

| Material | Zirconia(ZrO2) |

| Material Mix | Zirconia Powder + Binder Coloring Material |

| Size(mm) | 72 x 166 |

| Cage Type | 500g, 1000g |

| Slurry Temperature | 15~30(±2)C |

| Usage | Dental Restorations |

| Certificates | KFDA, ISO 13485, CE |

ROBO-ICM

| Product Name | ROBO-ICM (ICM-W500/1000) |

| Material | Zirconia(ZrO2) |

| Material Mix | Zirconia Powder + Binder Coloring Material |

| Size(mm) | 72 x 166 |

| Cage Type | 500g, 1000g |

| Slurry Temperature | 15~30(±2)℃ |

| Usage | Non-dental Purpose |

| Certificates | KFDA, ISO 13485, CE |

SOFTWARES

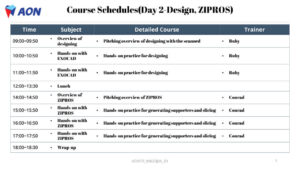

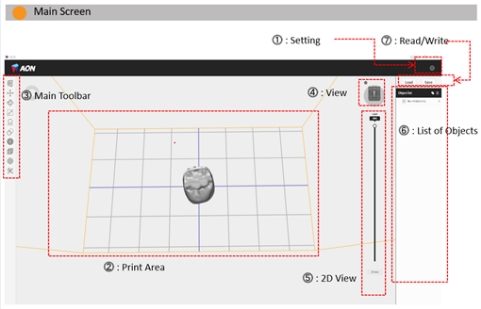

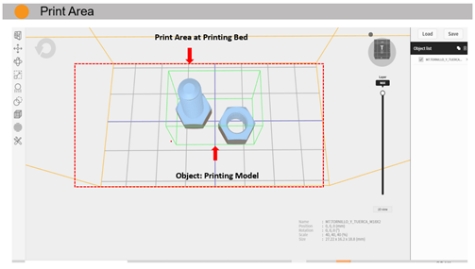

ZIPROS

ZIPROS is the user-friendly, easy and convenient slicing software for ZIPRO Dental and Industrial. End-user can complete the slicing works by a few mouse-clicking.

AON offers ZIPROS to the purchaser of ZIPRO Dental or Industrial for free.

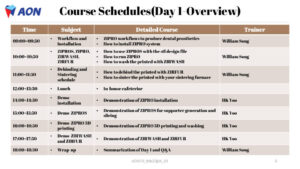

TRAINING AND CONSULTING

AON Global Training Center in Zir-Con Labs, Manila

AON provides various training courses to allow you to get a fulling understanding of how to use its products and the relevant production process. It must be an excellent opportunity noy only to understand the operating principles of AON 3D Printers, but also to acquire the knowledge to be able to produce high-quality ceramic outputs at dental and non-dental level.

As the leading technology provider of 3D printing systems for high quality of ceramic outputs, AON’s in-house experts have years of experience in areas such as ceramics engineering and technology, mechanical engineering for 3D printers and software engineering. As your reliable partner, AON offers the training opportunities to you and supports you with tailored training courses, enabling you to produce efficiently and to a consistently high quality.

These courses are individually tailored to suit different requirements and levels of previous experience.

Basic Training

This course is aimed to offer you the fundamental training to lead you on the right path. Learn the fundamentals of the DLP technology and understand the basics of operating AON 3D printer. You will learn the correct procedures of preparing, printing and post-treating your first outputs. Recommended either shortly before installation at AON HQ or during the set-up of AON 3D printer at your premises.

Advance Training

You will gain more knowledge about the advanced operating principles of AON 3D printers and acquire a comprehensive understanding of the AM production process. AON experts will give you walk-through training along the way to allow you to keep AON 3D printer running smoothly and produce efficiently. Recommended after 3-5 months of experience with AON 3D printer.

AS Service Training

This course is an excellent opportunity for experienced dealers and AS servicer to master the technical and practical knowledge needed for AS service to AON 3D printer and to stay ahead with the latest developments and innovations in the field. With this course, you will obtain a full understanding of how to fix the troubles shootings raised by your customers and/or how to replace key parts of the printer in enhancing your customer’s productivity. Recommended after 1 year experience with your machine.